Linings Division

Expert solutions for industrial refractory linings and protective coatings

Lining Division

Our Linings Division provides comprehensive refractory lining solutions for the oil and gas, glass, cement, lime, power generation, non-ferrous, and steel industries, ensuring optimal thermal efficiency, durability, and safety in high-temperature environments.

Our Services

-

Engineering & Design

Tailored refractory solutions based on operational requirements and industry standards.

-

Material Supply

Selection and supply of High-performance refractory materials, including bricks, castables, and ceramic fiber products.

-

Installation & Maintenance

Expert installation, repairs, and relining services to extend equipment lifespan and improve efficiency.

-

Inspection & Testing

Advanced diagnostics, thermal imaging, and integrity assessments to detect wear and optimize performance.

Our Specialization

Our crews are highly skilled and fully competent in installing castable refractory materials using a variety of advanced techniques, ensuring durability, efficiency, and precision in every application.

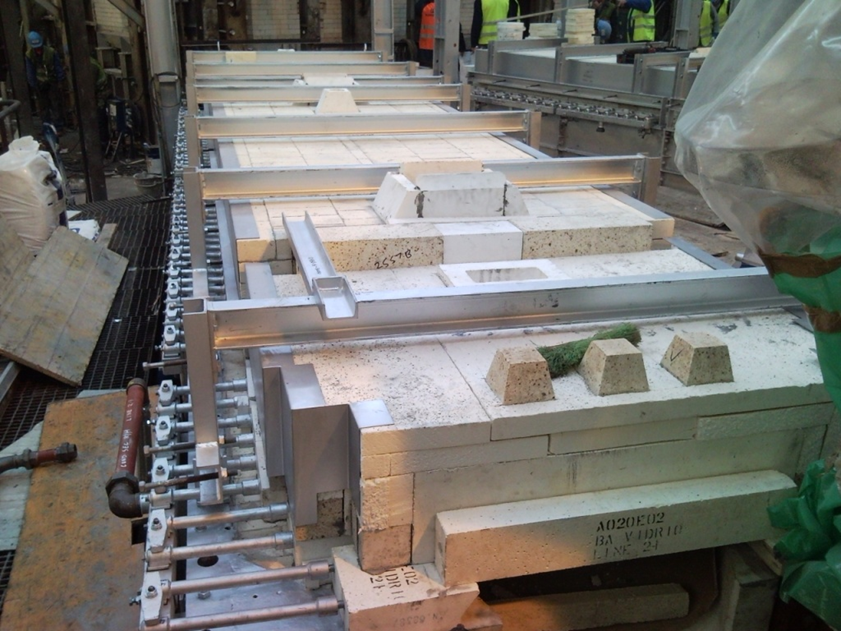

Bricking

Ensuring high durability, thermal efficiency and resistant to extreme temperature by Conventional Bricklaying, Keying and Expansion Joint installation. Providing precise alignment and placement for structural integrity, optimal bonding of dry and wet mortars, and allowing for thermal expansion and preventing cracking.

Form and Pour

A reliable method for installing dense and insulating castables, ensuring uniform thickness and strength.

Vibrocasting

Utilizing controlled vibration to achieve maximum density and minimal porosity, ideal for high-performance linings.

Dry or Wet Process

A fast and effective application technique for repairing and installing refractory linings, minimizing downtime. High-velocity placement of refractory materials, providing excellent adhesion and reduced rebound loss in demanding environments.

Industries We Serve

Oil & Gas

Specialized refractory solutions for high-temperature processing equipment in the oil and gas industry, ensuring optimal performance and safety.

Glass

Precision refractory linings for glass manufacturing facilities, maintaining consistent temperatures and extending equipment life.

Cement & Lime

Durable refractory solutions for cement and lime production facilities, optimizing thermal efficiency and reducing maintenance needs.

Non-Ferrous and Aluminum

Specialized refractory linings for non-ferrous metal processing, ensuring optimal performance in high-temperature environments. High-performance refractory solutions for aluminum production facilities, maintaining consistent temperatures and extending equipment life.

Steel

Robust refractory linings for steel manufacturing, ensuring optimal performance in extreme temperature conditions.

Power Generation

Reliable refractory solutions for power generation facilities, optimizing thermal efficiency and ensuring long-term performance.

Ready to Start Your Project?

Contact us today to discuss your lining service needs