Mechanical Division

Comprehensive Industrial Services

Comprehensive Industrial Services

We offer a full range of turnkey solutions, specializing in industrial demolition, installation, maintenance, repairs, and inspection services for industrial plants and facilities. Our expertise ensures seamless execution and optimal performance across all project phases.

Our experience spans conveying systems, crushers, finish mills, kilns, furnaces, chute work, ductwork, structural steel, plate work, and piping. With a strong focus on precision and efficiency, we deliver tailored solutions to meet the unique demands of each project.

Our mechanical projects range from small to medium-scale, including new construction, plant outages, preventive and predictive maintenance, heavy rigging, labor-intensive operations, and critical schedule-driven projects. We are committed to delivering high-quality, cost-effective solutions that maximize reliability and productivity.

Our work strictly adheres to ANSI, ASTM, DIN, AISC, ASME, NEC, FBC, ACI, ASCE, AWS, OSHA, and all other applicable codes, ensuring compliance with the highest quality and safety standards. Additionally, we provide comprehensive documentation, including PQRS, WPS, WPQS, NTRS, material quality certificates and quality controls records.

With a focus on precision, durability, and compliance with industry standards, we deliver high-quality solutions that enhance operational efficiency and equipment longevity.

Conveying Systems

The mechanical installation of conveying systems involves the precise assembly, alignment, and commissioning of equipment used to transport bulk materials efficiently within industrial plants. This process includes the installation of belt conveyors, screw conveyors, chain conveyors, bucket elevators, and pneumatic conveying systems, ensuring seamless material flow across production lines.

Our expertise covers everything from structural supports and drive components to rollers, pulleys, and alignment systems, guaranteeing optimal performance, reliability, and compliance with industry standards. With a focus on precision, safety, and efficiency, we deliver turnkey solutions that minimize downtime and maximize operational productivity.

Crushes and Vibrating Screens

The mechanical installation of crushers and screens involves the precise assembly, alignment, and integration of crushing and screening equipment to ensure efficient material processing in industrial plants. This includes the installation of jaw crushers, cone crushers, impact crushers, vibrating screens, and associated support structures.

Our process covers foundation preparation, structural steel assembly, equipment alignment, drive system installation, and conveyor integration, ensuring seamless operation and optimal performance. With a focus on precision, safety, and reliability, we deliver turnkey solutions that enhance productivity, reduce downtime, and meet industry standards.

Chute and Duct Work

The mechanical installation of chutes and ductwork involves the precise fabrication, assembly, and integration of material handling and airflow systems in industrial facilities. Chutes are installed to guide and control the flow of bulk materials efficiently, minimizing spillage and wear, while ductwork is essential for ventilation, dust control, and process air management.

Our expertise includes structural support installation, alignment, welding, bolting, and sealing to ensure durability, efficiency, and compliance with safety and environmental standards. With a focus on precision and reliability, we deliver turnkey solutions that enhance plant efficiency and operational performance.

Structural Steel

The mechanical erection of structural steel involves the precise assembly and installation of heavy steel frameworks that support industrial facilities, equipment, and infrastructure. Our services include lifting, positioning, aligning, and securing steel beams, columns, platforms, and support structures to ensure strength, stability, and compliance with engineering standards.

Through our trusted fabrication partners, we provide high-quality, custom-fabricated steel components tailored to project specifications. Our expertise in rigging, welding, bolting, and structural reinforcement allows us to efficiently execute projects of any scale, ensuring durability, safety, and seamless integration with other industrial systems.

Finish Mills and Rotary Kilns

The mechanical assembly of finish mills and rotary kilns is a critical process that ensures the efficient operation of industrial grinding and high-temperature processing systems. Finish mills refine raw materials to achieve the desired particle size, while rotary kilns facilitate thermal processing for applications such as cement production and ore processing.

Our expertise includes precision alignment of shell sections, installation of girth gears and pinions, assembly of drive systems, bearing and roller adjustments, and refractory lining support. As part of our comprehensive capabilities, we also supply high-quality gears and mechanical components, ensuring reliability, durability, and seamless integration for optimal equipment performance and longevity.

Drying Systems and Baghouses

The mechanical assembly of drying systems and baghouses involves the precise installation and integration of equipment designed for moisture removal and air pollution control in industrial processes.

Drying systems ensure efficient material drying through controlled heat and airflow, while baghouses are essential for dust collection and air filtration, maintaining environmental compliance and workplace safety.

Our scope includes structural assembly, duct and piping installation, fan and blower alignment, filter housing assembly, and support system integration. With a focus on efficiency, reliability, and compliance with industry standards, we deliver turnkey solutions that enhance process performance, reduce emissions, and ensure optimal operational efficiency.

Plate Work

The mechanical assembly of plate work in vessels such as cyclones, riser ducts, and other industrial process equipment involves the precise fabrication, cutting and fitting, and installation of heavy steel plates to form durable, high-performance structures. These vessels are essential for material separation, air and gas flow management, and high-temperature processing in industries such as cement, power, and petrochemicals.

Our expertise includes plate cutting, shaping, welding, bolting, and structural reinforcement, ensuring airtight, pressure-resistant, and wear-resistant assemblies.

Welding and Piping Lines

Our welding and pipeline installation services ensure the safe, efficient, and high-quality fabrication and assembly of piping systems for industrial applications. We specialize in the installation of carbon steel, stainless steel, and alloy pipelines, catering to industries such as oil & gas, petrochemical, power generation, and manufacturing.

Our expertise includes pipe fitting, welding, flange assembly, pressure testing, and non-destructive examination (NDE) to ensure structural integrity and compliance with industry standards. All welding procedures adhere to AWS, ASME, ANSI, ASTM, and other applicable codes, with comprehensive documentation, including Welding Procedure Specifications (WPS), Procedure Qualification Records (PQR), and Welder Performance Qualifications (WPQ).

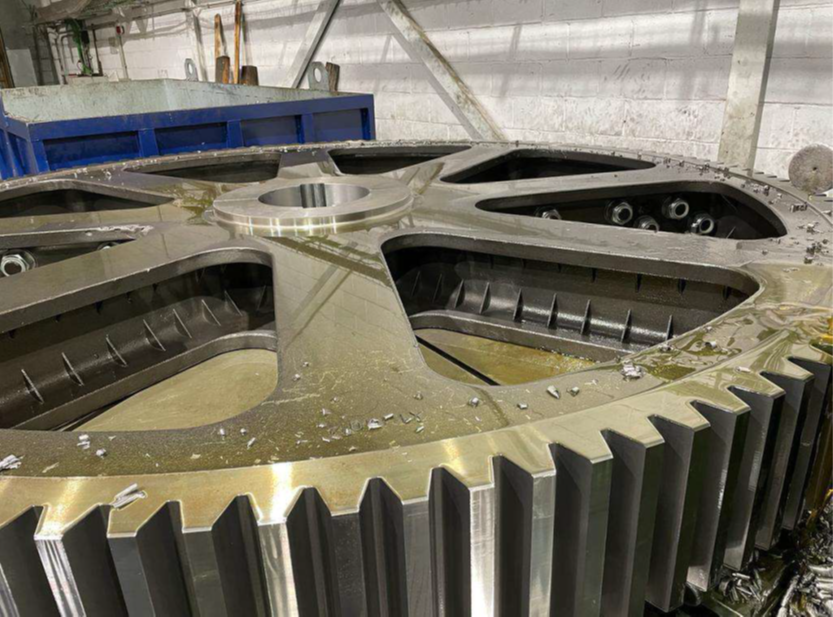

Fabrication and Supply of Gears

We partner with Engranajes Deusto, a company with more than 30 years of experience, specialized in gear manufacturing, hobbing and grinding gears for any kind of transmission. We can provide complete or customized solutions for our customers in many industrial areas such as automotive, equipment, shipbuilding, and rail industry, among others.

Placed in a productive plant of 17000 sqft, we have production capabilities and equipment to machine, manufacture and hob any kind of specific gear that our customers request us. Advance gear calculation software allows us to provide the technical support that our clients need to optimally design and size their components.

Process control, customer closeness and quality are the three pillars of Engranajes Deusto. We stand out for providing end-to-end services that enable us to control the whole process: design, manufacturing (including all required processes, from raw material management, handling, to any final adjustments to the pieces), packaging and delivery.

Product Range

Spurs, Straight and Helical Gears

- External: From module 1 and 10 mm diameter to module 40 and 3,000 mm diameter

- Internal: From module 1 and 40 mm diameter to module 12 and 3,000mm diameter

Cycloid Gears

Cycloid gears made based on the customer needs and specifications.

Bevel Gears

From module 1 and 20 mm diameter to module 10 and 1,000 mm diameter.

Other sizes may be available.

Chevron Sets

From module 1 and 40 mm diameter to module 40 and 3,000 mm diameter.

Wheel Gear and Worms

- Wheel Gear: From module 1 and 40 mm diameter to module 18 and 1,600 mm diameter

- Worms: From module 1 to module 14

- We also manufacture CAVEX worms and wheel gears

Splined Shafts

From module 1 and 20 mm diameter to module 10 and 500 mm diameter. For other measurements, please enquire.

Gears for Pumps

From module 1 and 20 mm diameter to module 25 and 1,500 mm. For other measurements, please enquire.

Racks

From module 1 to module 12.

Couplings

From module 1 and 40 mm diameter to module 12 and 800 mm diameter.

Ready to Start Your Project?

Contact us today to discuss your mechanical service needs